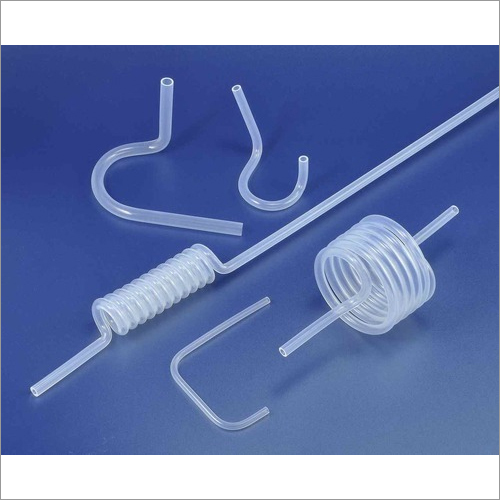

PTFE Tubings

Price 300 INR/ Meter

PTFE Tubings Specification

- Product Type

- PTFE Tubings

- Material

- Polytetrafluoroethylene (PTFE)

- Type

- Flexible Tubing

- Shape

- Round

- Technique

- Extruded

- Surface Treatment

- Smooth

- Standard

- ASTM D3295 / ISO 10993

- Outer Diameter

- 0.7 mm to 105 mm

- Length

- Up to 500 meters (coil) or custom cut

- Inside Diameter

- 0.3 mm to 100 mm

- Wall Thickness

- 0.2 mm to 3 mm

- Tensile Strength

- 2135 MPa

- Grade

- Virgin / Food / Medical

- Size

- Custom sizes available

- Color

- Milky White / Transparent

- Compression Set

- Creep-resistant

- Chemical Resistance

- Excellentresistant to most chemicals and solvents

- Applications

- Chemical, pharmaceutical, electrical insulation, laboratory

- Flammability

- Non-flammable

- Moisture Absorption

- <0.01%

- Hardness (Shore D)

- 5565

- Dielectric Strength

- 60 kV/mm

- Density

- 2.152.20 g/cm

- Temperature Range

- -200C to +260C

PTFE Tubings Trade Information

- Minimum Order Quantity

- 30 , , Meter

- Main Domestic Market

- All India

About PTFE Tubings

Technical specification

| Unit Length | 6m,>24m,upto 100 meters,24m,18m,12m,3m |

| Color | Red,Black,GREEN,Blue,White |

| Application | Drinking Water,AUTOMOBILES,CABLE PROTECTION,FOOD & PHARMA INDUSTRY,Gas Handling,Chemical Handling,Utilities Water |

| Size | 1/4 inch-1/2 inch |

| Single Piece Length | 3 meter,>36 meter,36 meter,18 meter,6 meter |

| Hollow Sections | Circular,CUSTOM MADE,Elliptical |

Exceptional Chemical and Thermal Performance

PTFE Tubings are engineered for environments requiring superior resistance to chemicals and solvents, maintaining stability across a wide temperature spectrum. Their inert property ensures reliable operation in aggressive laboratory, pharmaceutical, and industrial settings, minimizing contamination and maximizing safety.

Precision and Versatility

Produced via extrusion method, these tubings offer consistent wall thickness and smooth surfaces, ensuring minimal friction and effective insulation. Available in custom sizes and grades (virgin, food, medical), the milky white or transparent tubes cater to specific requirements for electrical, laboratory, and fluid transfer applications.

Certified Safety and Compliance

Meeting ASTM D3295 and ISO 10993 standards, PTFE Tubings provide assurance in regulated environments. Non-flammable and with nearly zero moisture absorption, these tubes are ideal for industries where safety and reliability are paramount, including medical and pharmaceutical domains.

FAQ's of PTFE Tubings:

Q: How can PTFE Tubings benefit my chemical processing applications?

A: PTFE Tubings offer unparalleled resistance to almost all chemicals and solvents, minimizing reaction risks and ensuring pure fluid transfer even in aggressive environments. Their stability under extreme temperatures and inert nature reduce contamination and enhance operational safety.Q: What is the recommended process for installing PTFE Tubings in electrical insulation projects?

A: For electrical insulation, select the appropriate wall thickness and diameter based on voltage and spatial requirements. PTFE tubings are easily cut to length and integrated into systems due to their flexibility and smooth surface, providing effective insulation with a dielectric strength of up to 60 kV/mm.Q: Where are PTFE Tubings typically used in laboratory settings?

A: In laboratories, PTFE Tubings serve for fluid transfer, gas handling, and sample delivery because of their resistance to chemicals and low moisture absorption. Their flexibility and custom sizing allow seamless integration into precise layouts without risk of contamination or absorption.Q: What grades of PTFE Tubings are available and when should each be used?

A: PTFE Tubings come in virgin, food, and medical grades. Virgin grade is suited for general industrial use, food grade for handling consumable substances, and medical grade for pharmaceutical and clinical applications demanding the highest purity and safety standards.Q: How is the quality of PTFE Tubings ensured during manufacturing?

A: These tubings are manufactured using an extrusion process, which guarantees precise dimensions and consistent material properties. Compliance with ASTM D3295 and ISO 10993 ensures each product meets international standards for safety and performance.Q: What applications benefit most from PTFE's non-flammable nature and creep-resistant compression set?

A: Industries prioritizing fire safety and dimensional stability, such as electrical insulation, pharmaceuticals, and laboratory operations, rely on PTFE Tubings. Their non-flammable nature and resistance to compression set provide consistent performance in critical and high-temperature environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Tubes Category

John Guest Stem Elbow

Price 300 INR / Number

Minimum Order Quantity : 10

Product Type : Other, Stem Elbow

Material : Other, Acetal (POM)

Length : 35 mm (Approximate)

Size : 1/4 Inch (OD x Stem)

John Guest Threaded Connector

Price 200 INR / Number

Minimum Order Quantity : 10

Product Type : Other, Threaded Connector

Material : Other, Acetal (POM)

Length : 42 mm

Size : 1/4 (Tube OD) x 1/4 (BSP Thread)

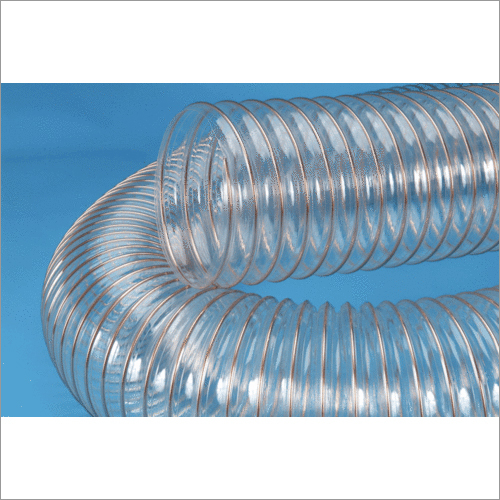

FEP Tubings

Price 100 INR / Meter

Minimum Order Quantity : 30

Product Type : Other, FEP Tubings

Material : Other, FEP

Length : 50 Meter (m)

Size : 2MM

PTFE Extruded Tubings

Price 200 INR / Meter

Minimum Order Quantity : 30

Product Type : Other, PTFE Extruded Tubings

Material : Other, PTFE

|

VIJAY ENGINEERING CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry