Ss Corrugated Hose

Price 200 INR/ Meter

MOQ : 1 Meter

Ss Corrugated Hose Specification

- Medium

- Liquids, Gases, Steam, Chemicals, etc.

- Connection Type

- Flanged, Threaded, Welded Ends, or as specified

- Cover

- Stainless steel exposed or with braided cover

- Reinforcement

- Single or double SS braiding

- Hardness

- Flexible/Not Applicable (corrugated design for flexibility)

- Shape

- Corrugated

- Material

- Stainless Steel (SS 304, SS 316, or as specified)

- Temperature

- -200C to +700C

- Pressure

- Up to 300 Bar (depending on hose type and size)

- Inside Diameter

- 6 mm to 300 mm

- Outside Diameter

- Varies by hose size and construction

- Corrugation Type

- Annular (standard), Helical available

- Color

- Metallic Silver

- Leakage Test

- 100% Hydrostatic & Pneumatic tested

- Fire Resistance

- High (suitable for high temperature environments)

- Application

- Chemical, Petrochemical, Power, Refineries, Cryogenic, and various industrial applications

- Bending Radius

- As per manufacturers catalogue, minimum flexible radius maintained

- End Fittings Material

- Stainless Steel

- Vibration Absorption

- Excellent for vibration and misalignment compensation

- Burst Pressure

- 4 times the working pressure (approximate)

- OEM Service

- Available on request

- Standard Length

- 1 meter to 15 meters or custom as per requirement

Ss Corrugated Hose Trade Information

- Minimum Order Quantity

- 1 Meter

- Main Domestic Market

- All India

About Ss Corrugated Hose

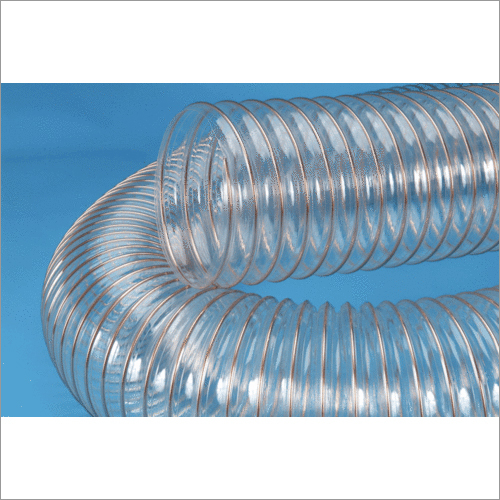

Ss Corrugated Hose

We are instrumental in supplying the best in line SS Corrugated Hose that are popularly known among our customers owing to their superior design and quality. These hoses are designed for industrial applications for the transportation of fluids and chemicals. Having made out of the high-grade stainless steel that is resilient and long-lasting, our offered SS Corrugated Hose are sure to last for an extended period of time.

Specification

| Color | Silver |

| Single Hose Length | 1m-6m |

| Size | 1/2 inch, 3/4 inch |

| Cross Section | Round |

| Material for Construction | Stainless steel |

Reliable Performance Across Industries

These corrugated hoses are meticulously crafted for demanding environments, excelling in chemical, petrochemical, power generation, refineries, and cryogenic operations. Their flexible design and robust stainless steel construction ensure suitability for transporting gases, liquids, steam, and various chemicals, even in harsh conditions.

Custom-Built to Your Specifications

Choose standard lengths from 1 to 15 meters or opt for custom sizes to fit your project requirements. End fittings come in a range of connection types, such as flanged, threaded, or welded ends, with materials such as SS 304 and SS 316 available to match process compatibility.

Engineered for Safety and Longevity

Every hose undergoes rigorous hydrostatic and pneumatic leak testing to guarantee zero leakage. The combination of high fire resistance, excellent vibration absorption, and burst pressure ratings at four times the working pressure delivers a safe and reliable solution for your operations.

FAQ's of Ss Corrugated Hose:

Q: How are the SS Corrugated Hoses typically used in industrial applications?

A: SS Corrugated Hoses are commonly utilized for fluid and gas transfer in sectors such as chemicals, power, refineries, and cryogenics. Their flexibility, high temperature and pressure resistance, and vibration absorption make them ideal for connecting equipment and compensating for misalignment or movement.Q: What customization options are available for hose length and end fittings?

A: You can select hoses in standard lengths from 1 meter to 15 meters or request custom lengths as needed. End fittings can be flanged, threaded, welded, or tailored according to your specific requirements, and are available in various stainless steel grades.Q: How is hose safety ensured during production?

A: Each hose undergoes 100% hydrostatic and pneumatic leakage testing before dispatch. Additionally, the design incorporates a burst pressure rating of approximately four times the standard working pressure, ensuring a safe margin during operation.Q: What temperature and pressure ranges can these hoses safely handle?

A: The hoses are designed to function between -200C and +700C and can withstand pressures up to 300 Bar, depending on the hose's internal diameter and construction.Q: What are the benefits of using stainless steel corrugated hoses over traditional hoses?

A: Stainless steel corrugated hoses offer superior resistance to chemicals, high temperatures, and fire. Their corrugated design enhances flexibility and vibration absorption, while their robust construction ensures longevity and reliable leak-proof performance.Q: In which situations is an annular or helical corrugation type recommended?

A: Annular corrugation is standard and suitable for most industrial applications needing flexibility and pressure performance. Helical corrugation is available on request, often selected for specific processes requiring a different torsional flexibility profile.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

VIJAY ENGINEERING CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry